Tunnelling

Quality construction, innovative safe designs, and sustainable solutions for every project.

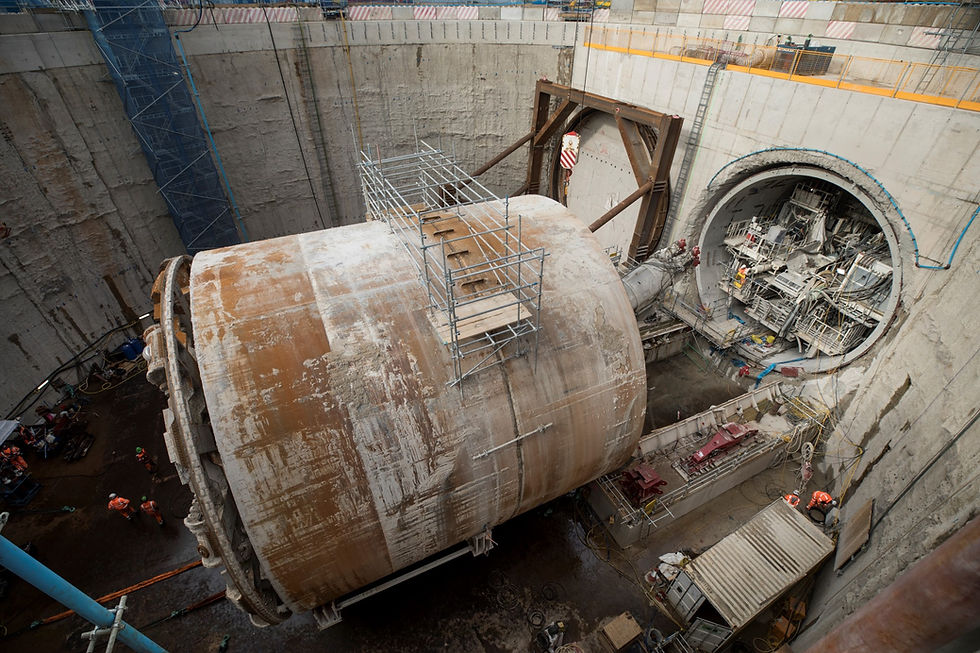

Modern Tunnelling & Rail Automation

Engineering Precision Beneath the Surface. This project offers a comprehensive analysis of mechanized tunnelling using Tunnel Boring Machines (TBMs) and their integration with modern automated rail systems, focusing on geotechnical interaction, machinery operation, and construction logistics.

Cutterhead and Gear Drive Mechanics

The TBM cutterhead is powered by a large-diameter main bearing system, driven by high-torque multi-stage planetary gearboxes. These gear drives adjust rotation speed and torque to suit varying geological conditions. Torque transmission from the drive motor to the cutterhead allows excavation through a combination of rotary shearing and applied thrust pressure .

Soil Conditioning and Face Pressure Control

To stabilize the tunnel face, EPB TBMs rely on maintaining the balance between earth pressure and the advancing thrust force. Soil is conditioned with foam and polymers to increase plasticity, reduce internal friction, and ensure uniform flow through the screw conveyor. In contrast, Slurry TBMs pressurize the excavation chamber with bentonite slurry, controlling groundwater inflow and face collapse in high-permeability soils .

Launch Shaft and TBM Start-Up Operations

Share your feature information here to attract new clients. Provide a brief summary to help visitors understand the context and background.

Segmental Lining and Grouting Operations

As the TBM advances, precast concrete segments are erected within the tail shield to form a ring. Sealing gaskets embedded in the segments prevent water ingress, while two-component backfill grout (typically cement-bentonite) is injected through ports to fill the annular void between the lining and the excavated ground, ensuring immediate support and ground stability

Muck Removal via Screw Conveyor and Slurry Lines

Excavated material (muck) is removed using a screw conveyor system in EPB TBMs, controlling volume and pressure discharge. The screw’s rotational speed is regulated based on cutterhead torque and soil density to maintain face stability. In slurry systems, muck is transported through pressurized pipelines, then separated in a surface slurry treatment plant before reuse or disposal .

Hydraulic Thrust System and Shield Steering

The TBM advances using hydraulic thrust cylinders, which apply force against previously installed lining segments. These jacks not only push the shield forward but are also controlled individually to enable steering and directional correction. This system allows precise control in curved alignments and variable ground conditions, minimizing settlement and ensuring alignment with the tunnel design path .

GET IN TOUCH

Request a Consultation

© 2026 Engineering Building & Infrastructure Pty. Ltd.

Manufactured Equipment and Materials, Constructed on Site.